Royal Mint Gardens DLR Encapsulation

In densely populated cities air space has become a premium commodity, developers are now seeking to buy air space above smaller structures and infrastructure in order to overbuild new superstructures. In 2017 we completed the first phase of an award winning complex rail encapsulation of the DLR line for Royal Mint Gardens London with the Carey Group plc & WSP. This encapsulation project constitutes a major piece of infrastructure and sets a precedence being the first construction works involving the enclosure of the DLR which carries over 123 million passengers annually.

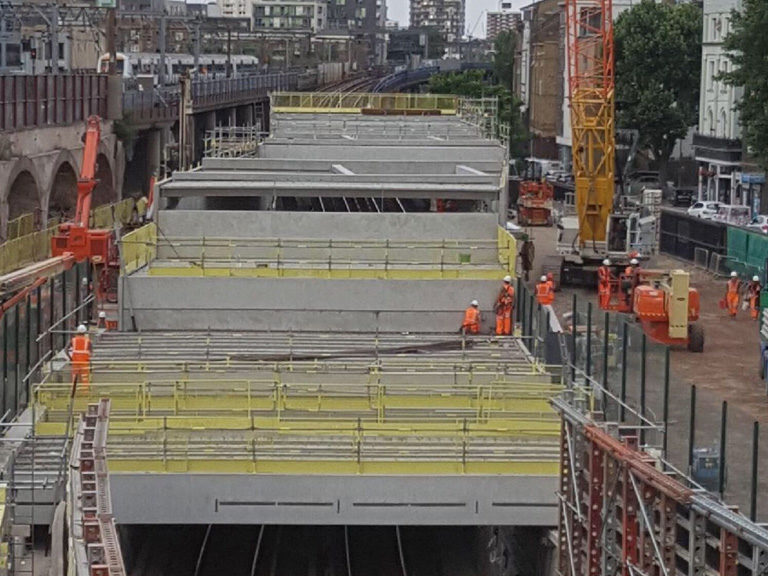

This particular project is a collaboration between Network Rail and IJM Land to develop the air-space above the Docklands Light Railway (DLR) to construct the Royal Mint Gardens development comprising of three new residential towers of 15, 14 and 13 storeys. Careys and Banagher Precast Concrete collaborated closely in order to encapsulate 150 m of the DLR line at Bank Station exit tunnel which is on a slope and has a very limited surrounding area, to protect the railway, provide fire and noise separation in the permanent condition while ensuring a robust suspended foundation for the new development.

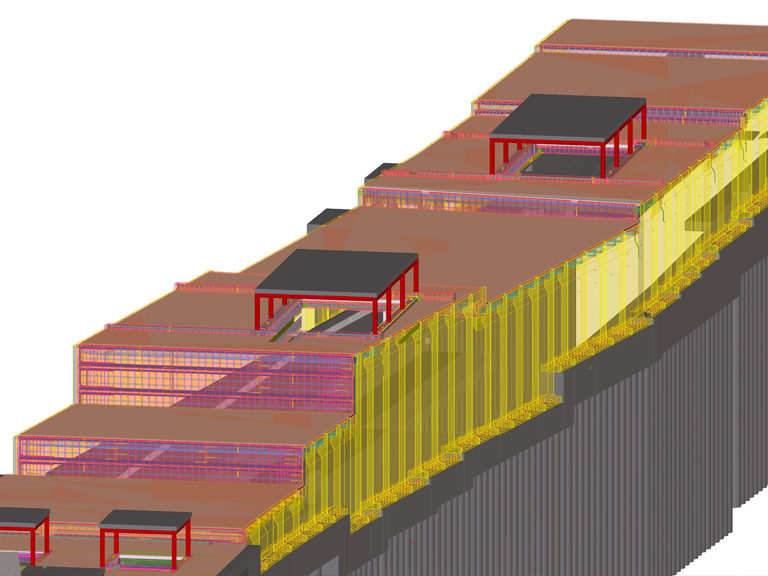

We designed this complex structure using BIM and used our expertise in precast to develop innovative solutions to create this tiered structure which incorporates escape platforms and ventilation pods and which has resulted in a structure which now serves as the building floor which can be subjected to an imposed floor load of 5kN/m². We completed a comprehensive structural model of the encapsulation which was overlaid against other models for mechanical, electrical and rail requirements.

By choosing to design with precast T-walls, slabs, beams & Banagher Double Tees this precast solution ensured the safety of the workers on site & of the passengers using the DLR line at all times. The bespoke multi-height T-walls were installed by Carey’s a beside the live rail line and the roof was lifted into position in just one 48 hour rail possession.

The Banagher prestressed MY Beams which are ideal for shorter spans were developed by us in 2007 as a more efficient bridge beam – using less concrete and reducing transport loads we call it our ‘Green Beam’, ideal for use in this central London location.

Working with Sheffield University and using BSF telescopic connectors eliminated the need for corbels, leaving a smooth soffit & architecturally ‘clean’ lines at concrete intersections, while reducing crane hook-time and ensured a safe, quick fit.

Technical Excellence

- The encapsulation structure has a minimum 120-year lifespan as per DLR requirements

- Provides fire separation and minimum 2 hour fires resistance

- Provides noise separation in its permanent condition

- Can withstand rail impact without compromising integrity

- Includes ventilation pods – comprising of a steel support frame with precast concrete slabs

- Sufficient space left under the platform to allow for services

- Concrete finishes – in areas concealed from view a basic finish, exposed surfaces a fine smooth finish

- Created a building floor which can be subjected to an imposed floor load of 5kN/m²

- Unit weights kept down for craneage

- Comprehensive structural model

- Research & development – BSF connectors cast into the beams

- Use of prestressed precast MY Beams – economical & environmentally friendly

Precast Concrete Supplied:

- 81 x Bespoke T- Wall panels of various dimensions

- 24 x Reinforced Concrete Beams

- 29 x Double Tee 360

- 11 x MY2 Beams

- 8 x MY3 Beams

- 24 x 125 mm wide slabs

#OutOfThinAir #PrecastRailSolutions #BanagherDoubleTee #BanagherMYBeams #ChallengeUs

Project Details

CLIENT

IJM Land / Network Rail / TfL

CONTRACTOR

Careys Civil Engineering